It is also advantageous for securing space because it is compact.

We recommend our "Linearstep Series" for the work linear motion part.

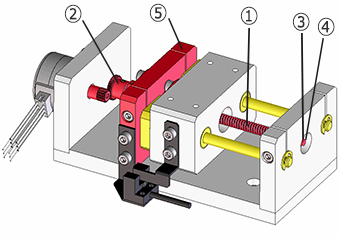

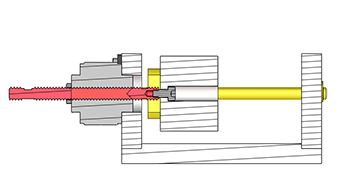

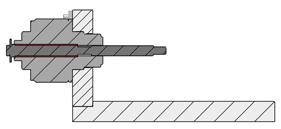

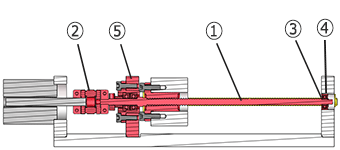

Comparison of rotary motor (PFC25) and Linearstep (PFCL25)

Comparison of rotary motor (PFC25) and Linearstep (PFCL25)

| Number | Parts | Rotary motor | Linear motor |

|---|---|---|---|

| ① | Lead screw | 〇 | × |

| ② | Gear | 〇 | × |

| ③ | Bearing | 〇 | × |

| ④ | C type retaining ring | 〇 | × |

| ⑤ | Bearing plate | 〇 | × |

Using a linear motor eliminates the need for the five parts (① to ⑤) used in a rotary motor.

Rotary motor(PFC25)

Linearstep(PFCL25)

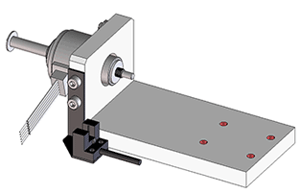

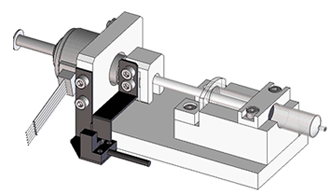

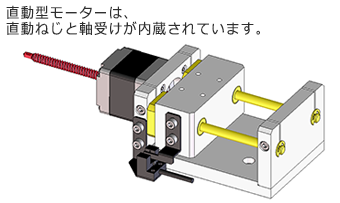

PM captive type (built-in captive type)

Since the PM captive type has a built-in captive mechanism inside the motor, mechanical parts such as guides can be reduced.

PM Captive Type1

PM Captive Type2

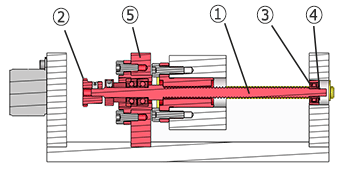

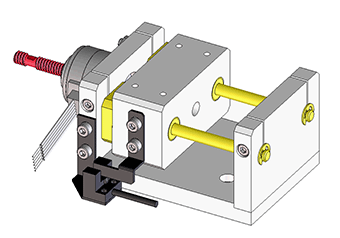

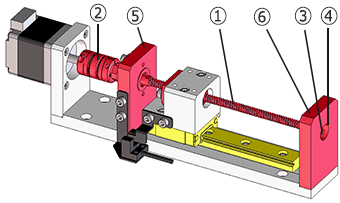

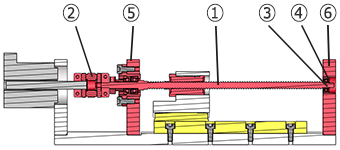

Comparison of rotary motor and Linearstep when using LM guide

| Number | Parts | Rotary motor | Linear motor |

|---|---|---|---|

| ① | Lead screw | 〇 | × |

| ② | Coupling | 〇 | × |

| ③ | Bearing | 〇 | × |

| ④ | C type retaining ring | 〇 | × |

| ⑤ | Bearing plate1 | 〇 | × |

| ⑥ | Bearing plate2 | 〇 | × |

Using a linear motor eliminates the need for the six parts (① to ⑥) used in a rotary motor.

Rotary motor PJP28T32E16

Linearstep PJPL2832E6(100)

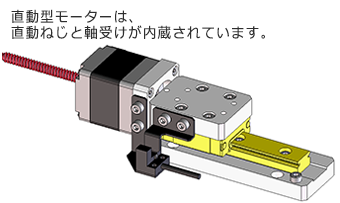

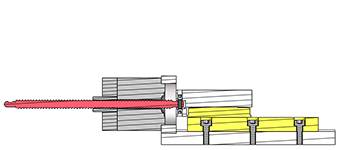

The linear motor has a built-in linear screw and bearing.

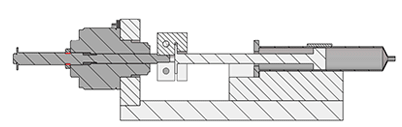

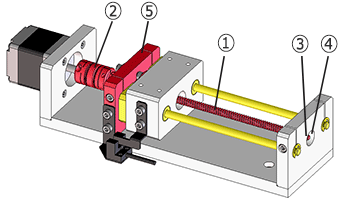

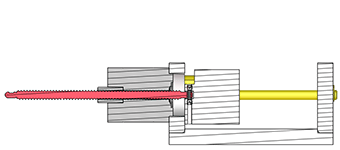

Comparison of rotary motor and Linearstep when using linear guide

| Number | Parts | Rotary motor | Linear motor |

|---|---|---|---|

| ① | Lead screw | 〇 | × |

| ② | Coupling | 〇 | × |

| ③ | Bearing | 〇 | × |

| ④ | C type retaining ring | 〇 | × |

| ⑤ | Bearing plate | 〇 | × |

Using a linear motor eliminates the need for the five parts (① to ⑤) used in a rotary motor.

Rotary PJP28T32E16

Linearstep PJPL2832E6(100)

The linear motor has a built-in linear screw and bearing.

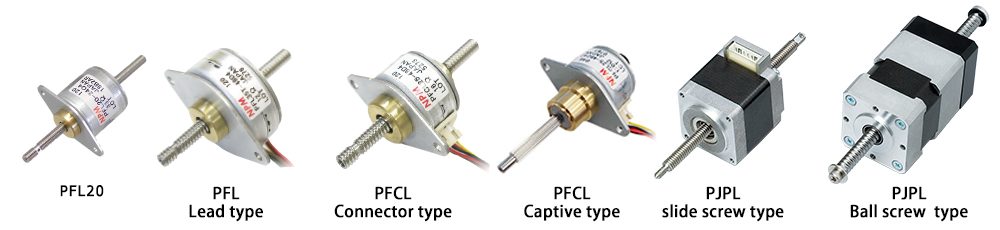

Linearstep Lineup