≪ Advantage ≫

・Reduction of mechanical design man-hours, mechanical assembly man-hours, and mechanical components.

・Contributes to compactness, space saving, energy saving, and cost reduction.

Comparison of parts reduction when replacing rotary motor with linear motor

For more information, see contents below.

Comparison of parts reduction when replacing rotary motor with linear motor

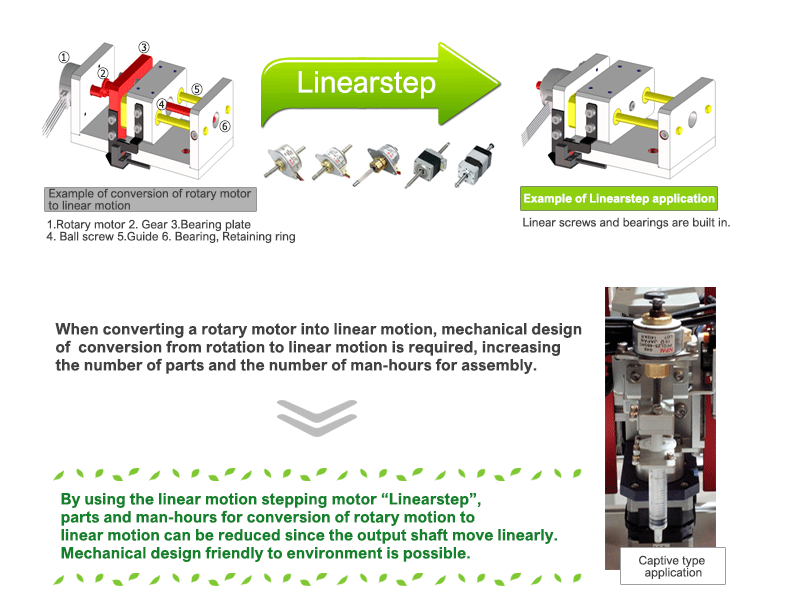

By changing rotary motor to linear motor, the number of parts such as bearings and couplings can be reduced, and the number of design and installation steps can also be reduced, resulting in significant cost reductions. It is also advantageous in securing space due to its compact size.

We recommend "Linearstep Series" for linear motion part of workpiece.

Comparison of parts reduction when replacing rotary motor with linear motor

By changing rotary motor to linear motor, the number of parts such as bearings and couplings can be reduced, and the number of design and installation steps can also be reduced, resulting in significant cost reductions. It is also advantageous in securing space due to its compact size.

We recommend "Linearstep Series" for linear motion part of workpiece.