LINEARSTEP

- Do you have any motors with a dustproof or splashproof construction?

- Can the motor performances be different if the rated voltages are different even if the resolutions are the same,?

- If the power supply is turned OFF (by power failure) for example while we use a linearstep in a vertical application, will the workpiece fall?

- What is the lifespan for a LINEARSTEP?

- Can I purchase a threaded shaft alone?

- Is it possible to change the movement stroke between 30 mm and 60 mm? If so, what is the minimum lot size?

- Can I fix the both shaft ends of a linearstep so that the motor itself moves?

- PJPL2832E4(100): Is this a LINEARSTEP with a ball-screw shaft?

- The shaft of PFCL25-48Q4C has stopped returning. Can it be repaired?

- We will locate the origin position by hitting the shaft end against the edge of the movable range. Will it effect on the repeatability of positioning?

- Can I generate some electricity by converting the vertical motion into the rotating motion in LINEARSTEP motors.

- Can I replace the front and rear ends of a threaded shaft of PFCL25?

- How much is the backlash (stroke)?

- Is it possible for PJPL motors to have a stroke of more than 100 mm?

- In the drawing of PFCL25, what does "T" stand for at the end of the shaft (M3T and Depth-4)?

- What is the positioning accuracy for repetitive motions?

- Do you provide a wrench or the like that can be used for the 2 x 2.9 wide threaded-shaft end of a PFCL25 motor?

- In the outline drawing of PJPL28T69E4A(200)R motor, there is a disk-shaped component at the left end of the shaft. What is it?

- The drawing indicates a rotor hub (manual operation part). What is it for?

- Regarding PFCL25-48C4C motor, is there any sealability (oil pressure, etc. ) on the shaft?"

- I am using PJPL2832E6(100) motor connected with AD1231 driver. The coil specification is 0.95 A, but if I set the drive current to 2.0 A in the driver, the flowing current may exceed the coil specification. What problems can I expect if I use the products in this state?

- The temperature of the motor has risen to about 70 °C. Does this cause a problem? Up to what temperature will be acceptable? Are there any effective ways to cool down the motor?

- Is it possible to extend the effective stroke to 80 mm? How much would be the price?

- Is there a built-in mechanical stopper at the front and rear sides of a motor? If not, does the shaft fall out?

- What is the angle of the thread on a linearstep shaft?

- Does the thread shaft happen to move under heavy load? Are the thrust force and the suppled voltage value are proportional to some extent?

- I want to know about wiring colors and A, /A, B, and /B-phases. Which direction does the motor axis move when I enter the CW direction electrical signal.

- My linearstep motor runs, but the thrust force is abnormally low. It stops when touched with a finger.

- Can the direction of the shaft be reversed?

- Are specifications and thrust characteristic data available?

- Can I perform a reciprocating motion of 30 mm stroke at 7 Hz?

- Is outdoor use possible?

- Can a linearstep be used vertically?

- Can I control a linearstep with a commercially available motor driver and a PC?

- Can a linearstep be used in a vacuum environment?

If you have any other questions or concerns, please contact us using the inquiry form below.

LINEARSTEP

- Do you have any motors with a dustproof or splashproof construction?

-

Unfortunately, we do not have at this point.

- Can the motor performances be different if the rated voltages are different even if the resolutions are the same,?

-

Motors of the same size with different rated voltages will have the same characteristics when you drive them at the rated voltages.

- If the power supply is turned OFF (by power failure) for example while we use a linearstep in a vertical application, will the workpiece fall?

-

No, it won't.

- What is the lifespan for a LINEARSTEP?

-

We can provide the information of "lifespan for a LINEARSTEP" separately. Please contact the NPM sales representvie or request through website.

- Can I purchase a threaded shaft alone?

-

We basically sell the threaded shafts as a set with the motors. However, it may be possible to sell them separately for customized products. Please contact us.

- Is it possible to change the movement stroke between 30 mm and 60 mm? If so, what is the minimum lot size?

-

The stroke can be customized.

We can produce from one piece. Please feel free to contact us.

- Can I fix the both shaft ends of a linearstep so that the motor itself moves?

-

There is no problem in using that way, but please be careful when moving the motor as the lead wires are not bend-resistant.

Also, if both ends of the shaft are tightly fixed, misalignment cannot be absorbed. Please pay attention to the mounting accuracy.

- PJPL2832E4(100): Is this a LINEARSTEP with a ball-screw shaft?

-

No, it is a slide-thread motor.

The ball-screw shaft type is PJPL28T series (Rolled ball-screwed).

- The shaft of PFCL25-48Q4C has stopped returning. Can it be repaired?

-

If the retainer at the rear end of a shaft gets bitten in the manual actuator part of a motor hub, it may not return.

Carefully rotate the manual actuator to return it.

- We will locate the origin position by hitting the shaft end against the edge of the movable range. Will it effect on the repeatability of positioning?

-

We do not recommend to hit the shaft end to the edge of a unit (=hard-stop) as it may cause threads to be bitten.

If you require repeatable positioning accuracy, we recommend the origin-return operation with a sensor.

- Can I generate some electricity by converting the vertical motion into the rotating motion in LINEARSTEP motors.

-

No, the thread mechanism of LINEARSTEP does not allow the reverse operation (thrust to rotation), so it cannot generate any electricity.

- Can I replace the front and rear ends of a threaded shaft of PFCL25?

-

Structurally possible, but be careful not to get dust on the threads or to apply sufficient grease, as this may change the characteristics.

- How much is the backlash (stroke)?

-

Although there is no clear definition, backlash (lost-motion) will occur to the extent of thread rattles of a shaft.

If you want to avoid backlash, you can use a spring or the like to pull the load to one side. Under conditions where a certain amount of thrust force is required, the pressed-allowance on preload springs in the bearing section may be taken into account in addition to the thread rattle.

Please contact us for details.

- Is it possible for PJPL motors to have a stroke of more than 100 mm?

-

It may be possible if the total length of the shaft is less than 150 mm.

- In the drawing of PFCL25, what does "T" stand for at the end of the shaft (M3T and Depth-4)?

-

"T" stands for tapping (female thread).

- What is the positioning accuracy for repetitive motions?

-

There is no specific standard for the positioning accuracy motion (because a threaded shaft is used).

In order to reduce backlash, you can take a countermeasure such as using a spring to pull the load to one side.

- Do you provide a wrench or the like that can be used for the 2 x 2.9 wide threaded-shaft end of a PFCL25 motor?

-

Unfortunately, we do not provide it.

- In the outline drawing of PJPL28T69E4A(200)R motor, there is a disk-shaped component at the left end of the shaft. What is it?

-

It is a stopper to prevent the shaft from falling off the motor and it has a cushion rubber to prevent collision.

- The drawing indicates a rotor hub (manual operation part). What is it for?

-

When the motor is not energized, the shaft can be manually stroked by turning this rotor hub directly by hand.

- Regarding PFCL25-48C4C motor, is there any sealability (oil pressure, etc. ) on the shaft?"

-

There is no sealability in the anti-rotation part.

- I am using PJPL2832E6(100) motor connected with AD1231 driver. The coil specification is 0.95 A, but if I set the drive current to 2.0 A in the driver, the flowing current may exceed the coil specification. What problems can I expect if I use the products in this state?

-

You can expect increase in heat generation due to overcurrent (overdrive), resulting burn-out of the coil, demagnetization of the magnet, and shortening the life of bearings.

However, it may be usable if the temperature rise is at less than 80℃ on the motor surface for a short period of energization time.

- The temperature of the motor has risen to about 70 °C. Does this cause a problem? Up to what temperature will be acceptable? Are there any effective ways to cool down the motor?

-

There is no problem with the surface temperature of the motor up to 80 °C.

To cool down a motor, you can use heat sinks, fans, and the like.

- Is it possible to extend the effective stroke to 80 mm? How much would be the price?

-

It is possible.

The stroke can be extended as long as the total length of the shaft is up to 150 mm, which is the same to the dimension shown in our catalog.

The unit price may vary depending on the quantity and dimension.

- Is there a built-in mechanical stopper at the front and rear sides of a motor? If not, does the shaft fall out?

-

Except for the captive type motor, there is no built-in stopper at both sides, so if the shaft exceeds the effective stroke, it will fall out.

(A captive type motor has a mechanical stopper only on the push-out side.)

Please take countermeasures in your system to prevent the shaft from falling out.

- What is the angle of the thread on a linearstep shaft?

-

The shaft specification of a linearstep is not disclosed due to its special threaded shape.

- Does the thread shaft happen to move under heavy load? Are the thrust force and the suppled voltage value are proportional to some extent?

-

The shaft only moves as far as the thread rattles. However, the shaft does not move in reverse by external load.

However, be careful not to overload on the motor, as it may lead to malfunction or damage to the thread .

Up to a certain degree, thrust force and supplied voltage are proportional, however doubling the voltage does not double the thrust.

Depending on the driving conditions, incresing the supplied voltage may cause saturation or worsen the situation. You can use a voltage higher than the rated voltage, but in this case, it is a trade-off for heat generation and thread durability.

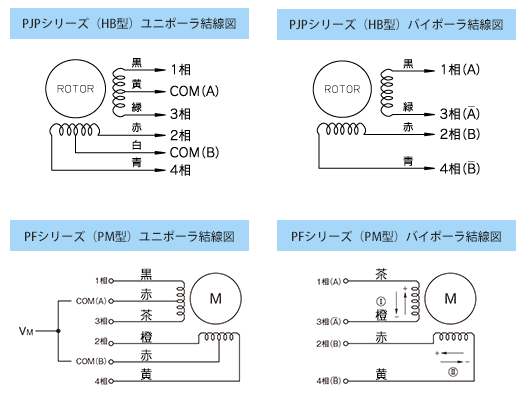

- I want to know about wiring colors and A, /A, B, and /B-phases. Which direction does the motor axis move when I enter the CW direction electrical signal.

-

The relationship between the wiring colors and the phases under the standard specification conforms to the PF series and PJP series (rotary stepping motors).

As for the direction of operation, CW direction signal is for pushing and CCW direction signal is for pulling.

(Please confirm them in our formal specification sheet.)

- My linearstep motor runs, but the thrust force is abnormally low. It stops when touched with a finger.

-

The threaded shaft of a linearstep must be used with a fixed rotation.

Anti-rotation for the shaft is mandatory in the mounting mechanism.

*Excluding captive (anti-rotation mechanism attached) series

- Can the direction of the shaft be reversed?

-

The following siding thread type linearsteps can.

PFCL25

PFL35T

PJPL2832

PJPL4233

Rotate the shaft by hand to remove it. Replace it carefully so that no dust adheres to the threads.

- Are specifications and thrust characteristic data available?

-

Specifications and thrust characteristics data for some models are available.

Please contact our sales representative or inquire in the support/inquiry page on NPM website.

- Can I perform a reciprocating motion of 30 mm stroke at 7 Hz?

-

The frequency is too fast to run with a linearstep.

The coarsest resolution of a linearstep is 0.05 mm (thread lead: 1.2 mm). (Coarse resolution = fast movement)

The applicable model is PFCL25-24 series with thread lead of 1.2 mm.

When the stroke length is 30 mm for 7 cycles, 30 × 2 × 7 = 420 mm is needed to move in 1 second.

To move 420 mm by advancing by 0.05 mm per pulse, 420 ÷ 0.05 = 8400 pps (pulse/s) is needed.

- Is outdoor use possible?

-

Use of the motor exposed outdoors may result in failures.

However, the outdoor use would be possible if sufficient measures were taken, such as dust-proofing, moisture-proofing, salt damage measures and the like.

Please determine whether or not to use the motor in your responsibility.

- Can a linearstep be used vertically?

-

When using a linearstep vertically, use 1/2 or less of the thrust characteristics as a guideline.

In the case of the ball-screw type, the shaft may fall when the excitation is turned OFF depending on the weight of the load.

- Can I control a linearstep with a commercially available motor driver and a PC?

-

If it is compatible with 2-phase stepping motors, it should be controllable.

However, we do not verify the operation with products from other manufacturers. Please contact the manufacturers.

- Can a linearstep be used in a vacuum environment?

-

No, it is not designed to be used in a vacuum environment.

More specifically,

・The motor generates gases due to the material used inside.

・The motor generates heat and exceeds the allowable temperature because the heat cannot be dissipated.