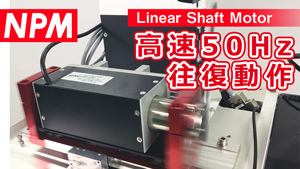

Shaft motor: high-speed reciprocating motion demo

This is a high-speed reciprocating motion demonstration using a linear shaft motor. The shaft motor is being operated at the frequency that can be driven for each motion stroke.

This is a high-speed reciprocating motion demonstration using a linear shaft motor. The shaft motor is being operated at the frequency that can be driven for each motion stroke.

Watch Video

Shaft motor: pressure control unit

High precision pressure control is available from very low pressure. The mechanism at the lower stage is being aligned in high resolution using a small DD motor.

High precision pressure control is available from very low pressure. The mechanism at the lower stage is being aligned in high resolution using a small DD motor.

Watch Video

Alignment stage / UVW stage

High precision control alignment stage using four shaft motors. X and Y-axis linear motions and θ motions are available.

High precision control alignment stage using four shaft motors. X and Y-axis linear motions and θ motions are available.

Watch Video

LINEARSTEP [PFL20] Dispensing demo

This is a dispensing demonstration that uses a linear step (direct-drive type stepping motor) [PFL20]. Diameter of PFL20 is 20 mm, which is the smallest in LINEARSTEP series.

This is a dispensing demonstration that uses a linear step (direct-drive type stepping motor) [PFL20]. Diameter of PFL20 is 20 mm, which is the smallest in LINEARSTEP series.

Watch Video

High-speed serial communication system: Motoinnet 64-axis control

The broadcast communication function of Motionnet allows simultaneous start with 64 axes and zero delay time.

The broadcast communication function of Motionnet allows simultaneous start with 64 axes and zero delay time.

Watch Video

Shaft motor: Pneumatic hybrid precision pressurization control

Pressurization from very low pressure to high pressure can be controlled with high precision.

Pressurization from very low pressure to high pressure can be controlled with high precision.

It is a hybrid high-precision pressurization control device with an unprecedented linear shaft motor and pneumatic servo.

Watch Video

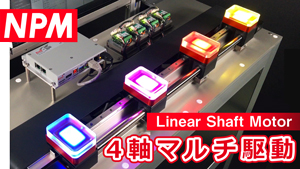

Shaft motor: 4-axis multi-drive

Linear shaft motors are linear brushless motors that enable high-speed, high-efficiency, and high-precision positioning controls. In the movie, four forcers on one single shaft are being controlled independently.

Linear shaft motors are linear brushless motors that enable high-speed, high-efficiency, and high-precision positioning controls. In the movie, four forcers on one single shaft are being controlled independently.

Watch Video

Direct-drive type stepping motor: LINEARSTEP dispensing demo

Linear step is a direct-drive type stepping motor that utilizes the structure of a conventional stepping motor.

Linear step is a direct-drive type stepping motor that utilizes the structure of a conventional stepping motor.

Rotational motion is converted into linear motion by a shaft with male screw and a rotor with female screw integrated.

Watch Video

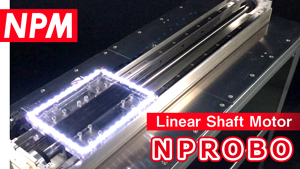

Shaft Motor: Single-axis slider robot- NPROBO

NPROBO is a linear servo actuator capable of high speed, high efficiency and high precision positioning controls.

NPROBO is a linear servo actuator capable of high speed, high efficiency and high precision positioning controls.

The principle of movement consists of a shaft with a cylindrical magnet in a stainless steel pipe and a coil part of a black aluminum casing that surrounds the shaft. When current is passed through the coil, a magnetic field is generated to drive linearly.

Watch Video

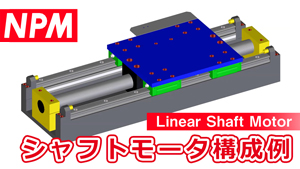

Shaft motor configuration example

This is an example of shaft motor assembly.

This is an example of shaft motor assembly.

Necessary parts are the shaft motor unit (shaft and forcer), linear guides, linear encoders, mounting brackets, cable carriers, etc. By fixing the shaft and forcer to the mechanism with a bracket, etc., the airgap between the shaft and the forcer is maintained.

Watch Video

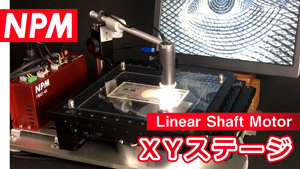

Shaft motor precision stage

Features

Features

• High precision

• Low vibration linear shaft motor is used

• Open frame structure

• XY travel ± 75 mm stroke

• Positioning resolution: 0.1 μm

Watch Video